Although there is a variety of equipment used for crushing rocks in the construction industry, jaw crushers are undoubtedly the best. A vast majority of the stones used for building get mined, and they come in irregular shapes. With the help of such equipment, the rocks get crushed to a desirable state for making of other relevant materials. Through technology, there as been a continuous improvement of the original model to create a version that works efficiently to meet the increasing construction needs. The gadget is gaining popularity because it offers its users with benefits as stated below.

Reliability.

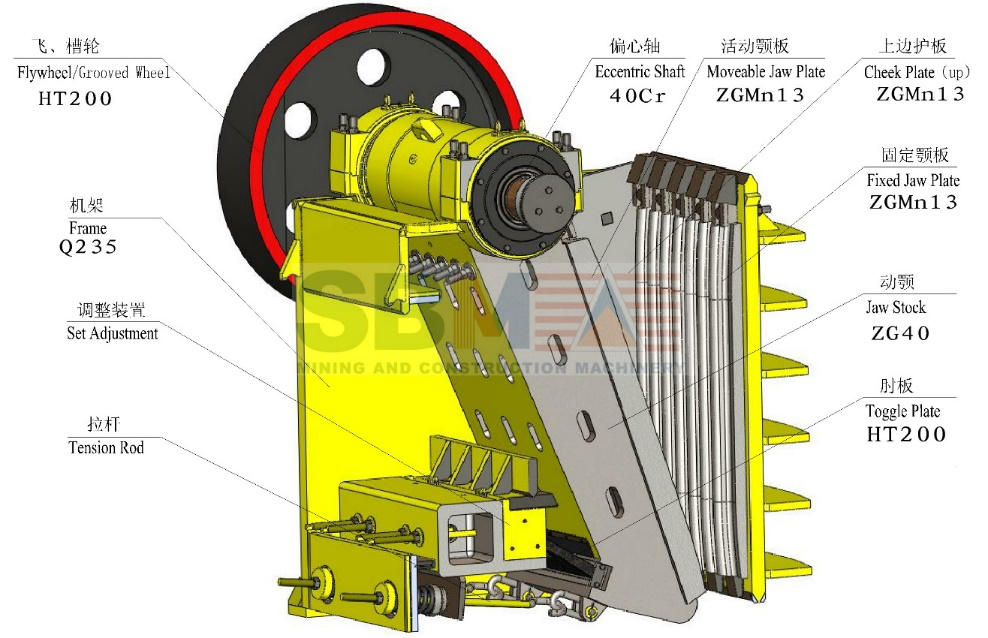

The best jaw crusher gets produced using robust materials that make it long-lasting to withstand any condition. The primary element is an alloy that gets joined utilizing a series of bolts and pins to ensure it can crush rocks of any kind for an extended period. Furthermore, it has other inbuilt components that provide sufficient support for better functioning. It has a honeycomb commonly known as cellular, which is durable to allow for the passage of crushed rocks without difficulties. The machine gets manufactured on engineering principles whereby the parts making up the frames go through casting to make it even stronger.

High-Efficiency Levels.

The jaw crusher in the Philippines works systematically to ensure that the crushing process is highly effective. First, the rocks move from one location to another at high speed, which translates to saving time. It has a free opening that is large to receive material in large quantities through specified rates until they reach the cavity. Down in the pit, there is a long stroke that acts as a platform for crushing while also regulating the rate of reduction to ensure quality end products. Furthermore, it is flexible in overseeing all kinds of tasks that the crusher can take.

Affordable Production.

Unlike any type of jaw crushers, the jaw crusher Philippines is very easy to install hence reducing the excess amount of input through labor. It requires a few days with very minimal expertise necessary, thus curbing wasting of time and also reducing installation costs. Modern designs come with an additional feature that allows the user to control it automatically through a remote. To function this way, you have to adjust the configurations of the crusher, feeder, and conveyor. Such action happens by upgrading the device with an automation system. Most of the sites where this device is required are full of rocks and other equipment hence exposing it to risks of either damaging or wear and tear. However, the essential parts of the crusher machine jaw have a shield to protect them from any accidents. Nevertheless, the other prominent parts can get replaced or repaired for it to function correctly.

If you have any additional functions that you would like the crusher to perform, you can speak to your supplier, and if possible, they will customize a model for you. Otherwise, you can work with the machine as it is or opt for other additional devices like a new feeder or flywheel to facilitate production without interference.